One of the primary uses for a bucket elevator is the handling of grain products. With such frequent use for an important job, a bucket elevator needs to be reliable, rugged and efficient. It may also be gentler than buckets designed for other industries to avoid damaging the grain.

At TAM Systems, we offer an array of bucket elevators for grain systems from industry-leading manufacturers and provide in-house expert setup and design services. We also service all the products we sell, so you can feel good about ensuring the longevity of your investment without much hassle.

We have a heart for farmers, and also know all about the needs of commercial grain processing. Plus, our team at TAM Systems offers competitive pricing, making us excellent partners when it comes to managing your project. Expertise in agricultural millwright work allows us to find and create the best solution for your business.

Bucket Elevator Manufacturers

The bucket and grain elevators we carry come from trusted manufacturers such as Honeyville, Sweet Manufacturing, Riley Equipment and Essmueller.

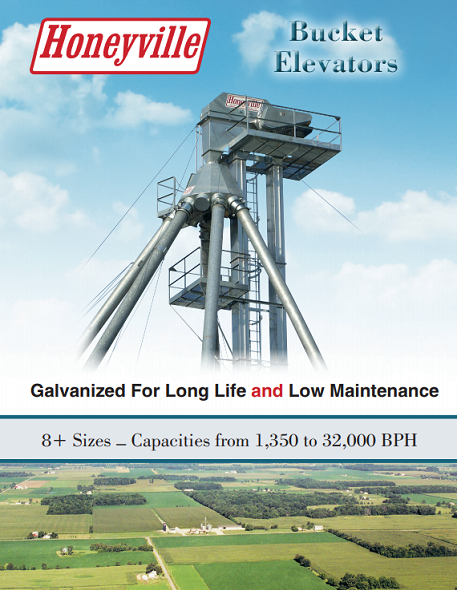

- Honeyville: Our long history of success with Honeyville makes them our first choice when specifying an elevator for your project. This brand carries bucket elevators in seven models, with capacities from 1,350 bushels per hour (BPH) to 32,000 BPH. All models have jig-welded, rugged components with galvanized finishes — built for longevity and low maintenance needs. The head covers are sectioned and hinged for easy servicing, while the elevator boot has easy-to-adjust take-ups for the boot pulley with various options for hopper width.

- Sweet Manufacturing: Sweet Manufacturing grain bucket elevator models reach as high as 55,000 BPH. They use galvanized USA prime steel and an all-bolted design. Other features include a hinged quick-latch inspection door for easy access, heavy-gauge trunking for support at various discharge heights and rubber belting specifically matched to strength requirements.

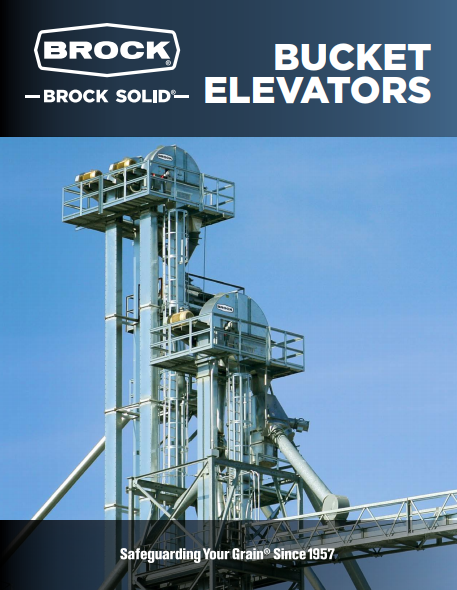

- BROCK: Trust bucket elevators from BROCK to feature smooth installation and durability. The brand offers galvanized and stainless steel options, with capacities of up to 60,000 BPH. BROCK considers the ease of millwright work, so installation and maintenance can be smoother processes. All of their bucket elevators have heavy-duty motor mounts with torque arm anchorage points, along with take-up boot sizes that include 18-inch, 24-inch and 30-inch pulleys in addition to the more common 36-inch, 42-inch and 48-inch sizes.

- Essmueller: Essmueller’s grain bucket elevators have capacities of up to 80,000 BPH and parts built for safety, with Occupational Safety and Health Administration (OSHA)-compliant hazard components. They come in painted, stainless steel and galvanized finishes with self-cleaning and gravity boots.

Custom-Designed Grain Bucket Elevators

No matter which grain elevator distributor you go with, customization can allow a grain bucket elevator to fit your existing setup perfectly. At TAM Systems, we offer 3D design services and can map out the project far in advance, so you know what to expect. We’ll make the customization process efficient and ensure you get a product suited to your farm or company’s specific needs.

To start working with TAM Systems on your newest grain bucket elevator, submit a contact form or give us a call at 717-432-9738 today.