Grain bins play a critical role in storing and protecting dry grains such as wheat, corn and soybeans. However, like any other piece of equipment, they are subject to wear and tear. Several uncontrollable events can affect a grain bin’s lifespan. In the sections below, we will dive into some tips to help you determine whether it is time for you to replace your grain bin or if it merely needs some repairs.

Grain Bin Lifespan

How long do grain bins last? Circumstances beyond your control — including inclement weather and geographical location — may shorten your grain bin’s usable lifetime. However, you can take proactive steps to make your bins last longer, including preventive grain bin maintenance and repairs. A well-kept grain bin can last decades before you need to get it replaced.

Common Grain Bin Problems Solved With Repairs

It’s possible to repair some damage instead of replacing the entire structure. Some of these problems include roof repairs, dented panels and cracks. Often, you can repair cracks and dents on the sides of the bin by replacing the damaged sheet of metal.

A few types of roof damage call for repairs.

- Concrete damage: When areas of coating wear away and expose poorly maintained concrete decking to the elements, it can cause the concrete to spall and a loss of the overhanging edge. Repairing this type of damage will require grain bin sealing for the perimeter edge.

- Loss of coating: Over time, the protective coating on a grain bin’s roof will wear away, causing the material beneath to deteriorate. When this occurs, peel back the deteriorated roof coating and replace it to prevent moisture from traveling between the membrane and the deck.

- Difficult roof access: For grain bins with less accessible roofs, regular maintenance is paramount. Because this area is harder to regularly check on, dirt and sediment buildup can start causing the roof to deflect and settle, ultimately allowing water into the bin and leading to roof failure.

When grain bin roofs are beyond repair, there are still two options available to make them serviceable. These include a single-ply replacement and a liquid application.

- Single-ply replacement: This solution includes adhering a lightweight thermoplastic membrane to the roof. This membrane outperforms taped and built-up roof seams and does not allow vegetation to grow.

- Liquid replacement: If your grain bin’s roof is not a good candidate for single-ply replacement, this method applies a liquid polyester resin and fleece mix to form a reinforced monolithic waterproofing membrane.

Grain Bin Problems Requiring Replacement

You can repair most issues you run into with your grain bins. However, some circumstances dictate when it is time to replace the entire structure. Damaged areas left unattended for an extended period will only create more issues. For example, a primary reason for having to replace a grain bin is significant damage to the structure’s foundation and anchor components.

Weather Damage

Now that we have covered some issues affecting your grain bins’ longevity, let’s look at one of the most damaging and unpredictable factors that can take a toll — weather.

- Wind: Wind might be the first thing that comes to mind when you think of severe weather. Unfortunately, wind can be a significant concern for those who own steel bins, especially when they are empty or partially filled. Wind damage can include dents, collapsed roofs and possibly overturn the whole bin. Concrete bins are primarily impervious to wind unless they are experiencing the late stages of decay.

- Ice: When ice forms in the cracks of a concrete grain bin, it can cause significant problems. When water gets into the tiny cracks of a grain bin and freezes, it expands, ultimately enlarging the crack. Ice can damage the grain bin’s roof and structure, threatening their stability over time.

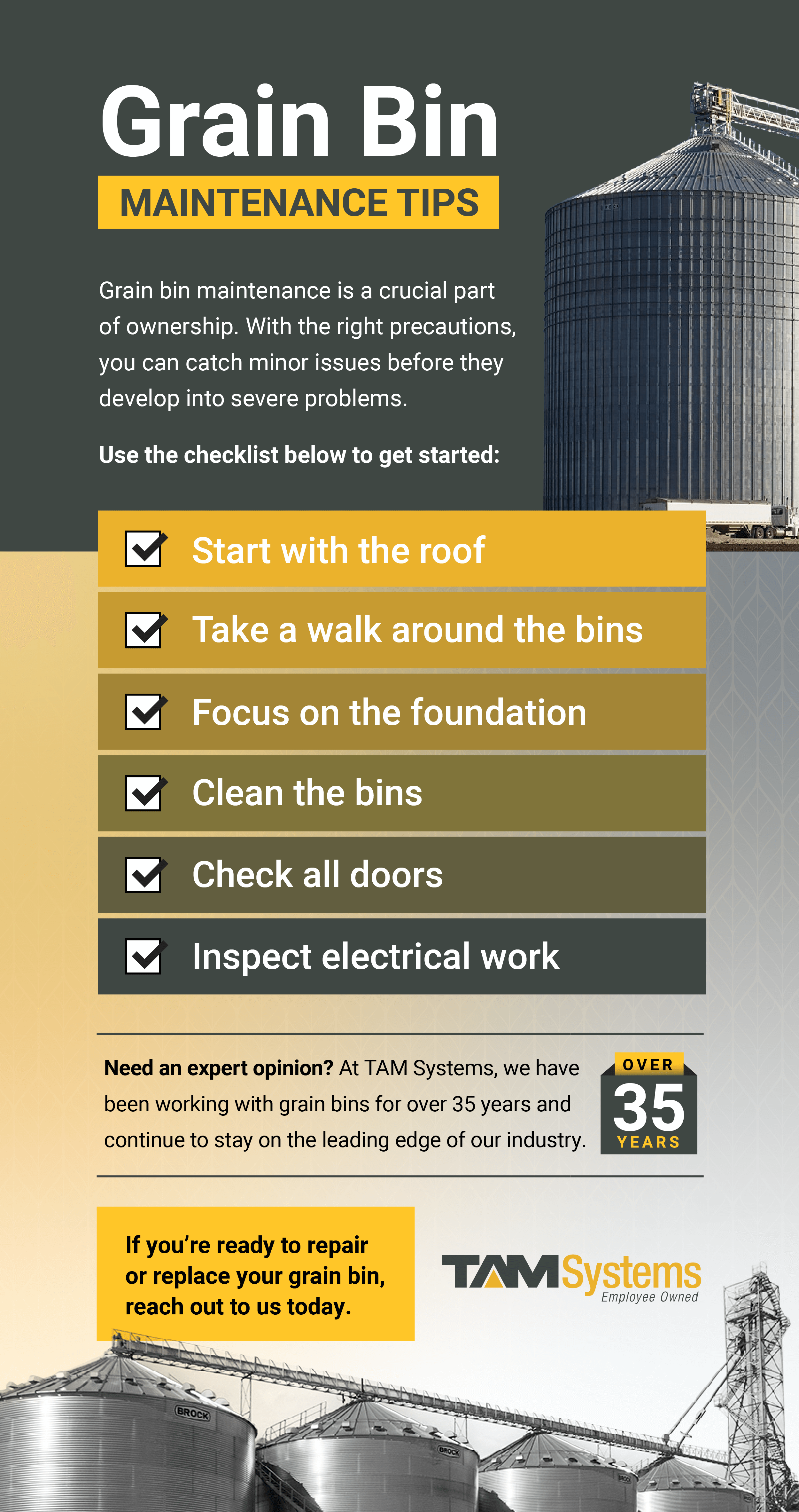

Grain Bin Maintenance Tips

One of our top tips for grain bin owners is to have an expert come and assess grain bin damage at least once a year. In the meantime, you can take steps to catch minor issues before they develop into severe problems. Use the checklist below to get started.

- Start with the roof: The grain bin’s roof can be a vulnerable area. Look for rust, signs of grain bin leaks and loose bolts. Check the roof panels and support ribs. If you have any debris on your vents, clean them up.

- Take a walk around the bins: Search for any evident signifiers of wear or undue stress.

- Focus on the foundation: Ensure it is level, without any gaps that could allow moisture or pests to enter the bin.

- Clean the bins: Sweep out old, unused grain and remove any rust and corrosion.

- Check all doors: Ensure their seals remain watertight. If you find any flaws, address them quickly.

- Inspect electrical work: Ensure all connections are secure and there are no frayed wires.

Get an Expert’s Opinion

At TAM Systems, we have been working with grain bins for over 35 years and continue to stay on the leading edge of our industry, providing quality grain systems to our customers. So, if you’re ready to repair or replace your grain bin, or you need an expert to help you decide, reach out to us today!