Grain bins and silos are two of the best-known types of grain storage towers on farms these days. Understanding the fundamental differences between these farmland staples is essential for choosing the right structure for your farming facility. Depending on your work, your budget and the amount of space you have to work with, either choice will be better for your purposes.

To help you distinguish between the two, this article explains what grain bins and silos are, what each structure can store and the primary distinctions between silos vs. grain bins. Keep reading to find out the details about grain bins and silos, and how each could benefit your operations.

What Are Grain Bins?

Grain bins typically look like broad, short buildings made from corrugated or smooth metal. Corrugated metal grain bins tend to have a uniform shape of a peaked roof atop a cylindrical body, often with doors and ladders on their sides. While grain bins are a popular grain storage system option for small farming operations, they are also common in more extensive grain storage facilities.

In general, grain bins feature various ventilating elements, such as temperature systems and roof vents, because they require ample airflow. Well-engineered, premium grain bins will also include these components to meet the needs of today’s complex agricultural environment.

- A high-capacity roof designed to handle heavy snow and equipment loads, such as supporting large conveyors

- Easy-open access doors that don’t require any tools and are two rings tall, so there’s no need to squeeze

- A sturdy tubular handrail next to the roof opening to assist a smooth entry and exit

- A high-strength aeration floor that facilitates sufficient, uniform air distribution and simplified cleaning

- Cushion boxes to protect the grain from potential harm during free fall by providing a soft landing

- Advanced grain aeration systems that combine the highest-quality fan and ventilation options to keep grain from spoiling or getting damaged

- Flow valves that control the rate at which the grain moves through the grain handling system

- Safety precautions and comfortable egress options, such as a ladder-climbing system with rest platforms and a case, adequate eave platforms and handrails along the path to the bin peak

- Single-piece steel lids that seal shut for a weather-tight fit and open broadly to provide a space wide enough to receive portable conveying equipment

- A solid foundation designed to support the massive grain weight while keeping the entire grain bin structure secure in high winds and other inclement conditions

What Is a Grain Bin Used For?

Thanks to all the outstanding features listed above, a grain bin is perfect for storing grain products like oats, soybeans and barley. Because the grain stored in grain bins is typically for human consumption, the grain bin must keep its contents dry, uncontaminated and pest-free until shipping time.

Keeping the grain dry is vital because moisture retention can cause the goods to spoil. However, applying too much heat to the grain can result in shrinkage, which decreases profit. To avoid either of these extremes, a grain bin’s ventilation and temperature systems must create a well-balanced environment at the ideal equilibrium.

Besides storing grain for human food products, grain bins can also house grains used for animal feed or fuel. Regardless of the grain’s eventual use, a grain bin’s corrugated walls can help preserve grain quality by protecting the goods against pests and moisture.

What Are Silos?

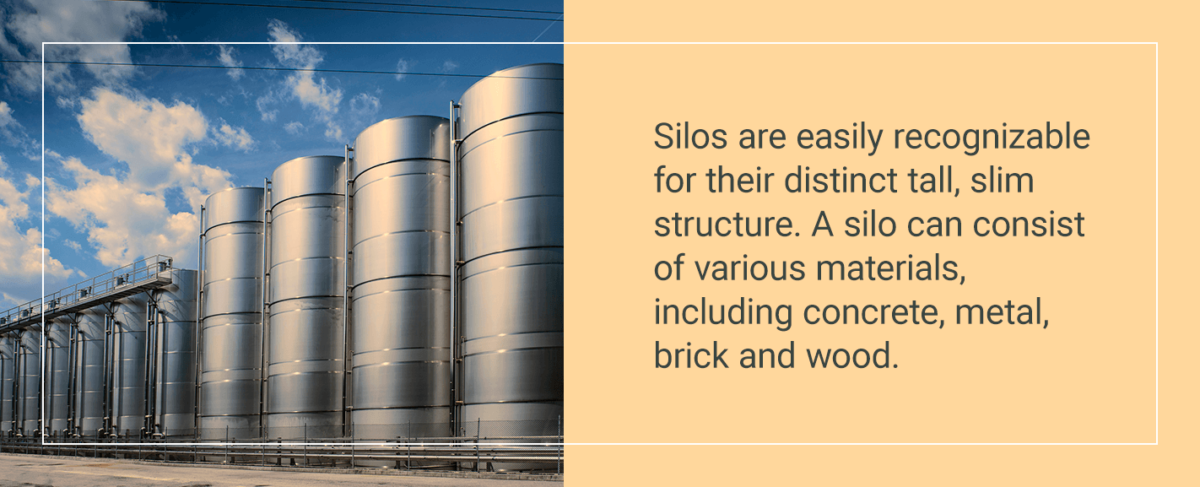

Silos are another staple of grain storage that are typical features on farms with cattle, but are sometimes on other farms, too. Silos are easily recognizable for their distinct tall, slim structure. A silo can consist of various materials, including concrete, metal, brick and wood.

While there are several silo formations available, these are the three main types of silos you’ll see on farmland.

- Tower: A tower silo is a familiar farmland sight with its traditional tall cylindrical shape. The tower silo’s stretched-out design makes it convenient to fit multiple silos on a smaller plot of land. Though most farmers load and unload from the top of the silo, bottom unloaders do exist.

- Bunker: A bunker silo is a trench consisting of human-made walls and a natural earth floor. Bunker silos are most often concrete structures covered with airtight tarps to protect the goods inside. To load and unload materials in bunker silos, farmers use tractors and loaders.

- Bag: As its name implies, a bag silo involves using plastic bags to store goods. Bag silos are airtight to shield their contents from external factors and can be more efficient than conventional silos because of their flexibility. While a bag silo cannot store quite as much as tower or bunker silos, it can house a substantial amount of goods within a compact space.

What’s a Silo Used For?

No matter which type it is, a silo stores silage, which is the term for fermented grasses that get used as feed for livestock. In addition to silage, some silos may store grain, cement or wood chips. It is crucial to keep livestock feed in pristine condition because cattle rely on it during the colder months, when foraging is scarce.

Silos allow silage to maintain its perfect form by creating an environment that encourages the grasses to acidify without spoiling. The delicate fermentation process begins with packing the grasses together tightly to deprive the interior environment of oxygen. Next, introducing a microorganism may speed up fermentation. Over time, the silage goes through the phases of fermentation before reaching stability.

Silo vs. Grain Bin

While both are viable grain storage options, grain bins and silos have a few crucial differences that affect which structure is right for a farming operation. Ultimately, the main distinctions between grain bins and silos break down into three categories — appearance, grain storage and function.

Here is how grain bins and silos differ within these areas.

1. Silos and Grain Bins Have Unique Appearances

While grain bins and silos are both cylindrical, there are a few notable differences in their looks. Grain bins can vary in shape, ranging from squat and broad to tall and slender, and have peaked roofs typically made of metal. However, silos tend to be more uniform in shape, but vary in materials. Silos are generally slimmer and taller with a domed roof and come in concrete, metal, brick or wood.

2. Grain Bins Store Grain While Silos Store Silage

An essential difference between silos and grain bins is the type of grains they store. Grain bins store dry grains, such as wheat, corn, oats, seeds, soybeans and barley, most commonly used for human consumption or to make fuel. On the other hand, silos are ideal for storing the fermented pasture grasses known as silage, which feed livestock throughout the winter.

3. The Function of These Grain Storage Towers Differ

Because they store different types of grains, silos and grain bins have inherently distinct functions. A silo’s unique design promotes fermentation to preserve the silage. In contrast, a grain bin’s purpose is to keep its contents dry, undamaged and pest-free. To accomplish this, a grain bin must allow for adequate aeration and maintain appropriate humidity and temperature levels to prevent spoilage.

Contact TAM Systems to Discuss Your Grain Bin Options

If a grain bin sounds like the right grain storage structure for your farming facility, check out the wide variety of durable, vented steel grain bin models from TAM Systems. We engineer our high-quality grain bins to provide your grain with the most protection possible to preserve its value.

We also provide custom design options to ensure you get the perfect grain bin for your property. Regardless of your project’s size and scope, TAM Systems is happy to organize its design and manage the details to ensure the project goes smoothly from beginning to end.

Contact TAM Systems today to receive a free quote and learn more about grain bins’ many benefits.